One AI for all cases -your production has never run so smoothly

Do potential disruptions and delays caused by maintenance work cost you nerves and your business money? The Predictive Maintenance solution based on artificial intelligence helps you stay one step ahead of these situations and only face them in complete serenity – if at all.

Schedule maintenance work at the right time and elegantly circumvent downtimes.

Predictive maintenance lets you make efficient use of machine data because AI identifies abnormalities in behavior before a physical problem arises. This gives you unprecedented freedom to act.

By using neural networks to identify responsible patterns that would otherwise be lost in the daily data stream, our AI also allows you to plan downtime & maintenance significantly better.

This saves your company from inappropriate maintenance work & avoidable machine problems and instead guarantees a smooth process.

Perfectly timed maintenance intervals increase your productivity

When things run like clockwork

Artificial intelligence takes your production line planning to the next level. Data-supported monitoring allows you to optimize the timing and effectiveness of your daily production routine. In addition to this, data-based predictions help you catch disruptions in the early stages.

Your benefits at a glance

- Reduce downtimes

- Cut down on disruptions and outages

- Increase the service life of machinery and equipment

- AI calculates the optimal maintenance time & speeds up service time

- Improve deployment, maintenance, and machine planning

- Improved productivity and performance of the machines

- Options for individual optimization

Stay cool - switch on the AI

These AI features help you understand your machines better.

Preprocessing

#data #filtering #acquisition

In preprocessing, our approach is to look at your machines and data domains in minute detail. Based on the results, we design the structure through which this information can be fed into the AI system automatically in the best possible way.

Feature Engineering

#criteria #kpis #features

Once the data have been prepared for further processing, we work together with the responsible persons on your side to precisely address the relevant characteristics of the data records. During this process, we define the significant measured variables and individual parameters.

Anomaly Detection

#pattern #anomaly #detection

After the AI understands your machines and their production processes, it can detect deviating behavior from real-time data and respond accordingly. As a result, you will be notified about the status of your machines in the shortest possible time.

Neural Networks

#neuralnetworks #deeplearning #edgeai

We will accompany you in successfully implementing the most modern technologies for your company. Through the use of so-called neural networks, we can considerably improve the predictions of machine behavior and service planning.

Explainable AI

#explAI #understanding #noblackbox

Apart from the critical details for upcoming maintenance intervals and the condition of the machines, it must additionally be understandable where and why the AI makes these decisions. This allows you to recognize & drive further optimizations in the operating process into the future.

Maintenance is mandatory, predictive maintenance is a smart choice.

To keep up with the competition, tough pricing measures often have to be taken. But, when you don’t want to reduce your staff or sacrifice quality, we can offer you the perfect solution.

The perfect solution is combining predictive maintenance with AI. By doing so, we can automate your production operations and the associated maintenance periods and thereby improve them substantially. This newly acquired understanding of the critical factors behind production lines will itself increase the quality of line processes.

Long stoppages & downtimes are costly, so what are you waiting for? Get the competitive edge of AI at your premises now.

Request

a free

Demo

You too can benefit from the advantages of AI-supported Predictive Maintenance. Request a non-binding personal consultation with our AI experts now.

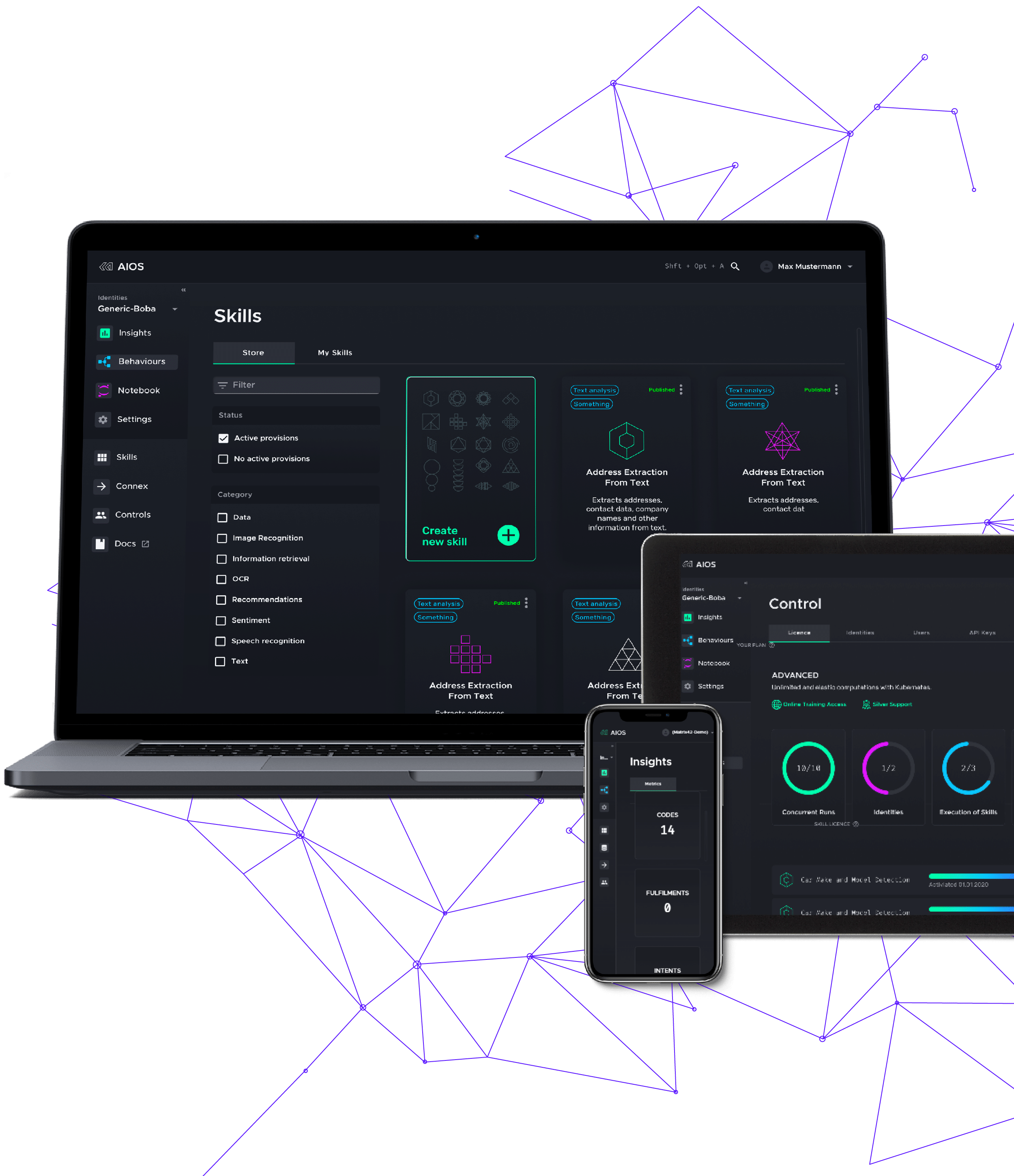

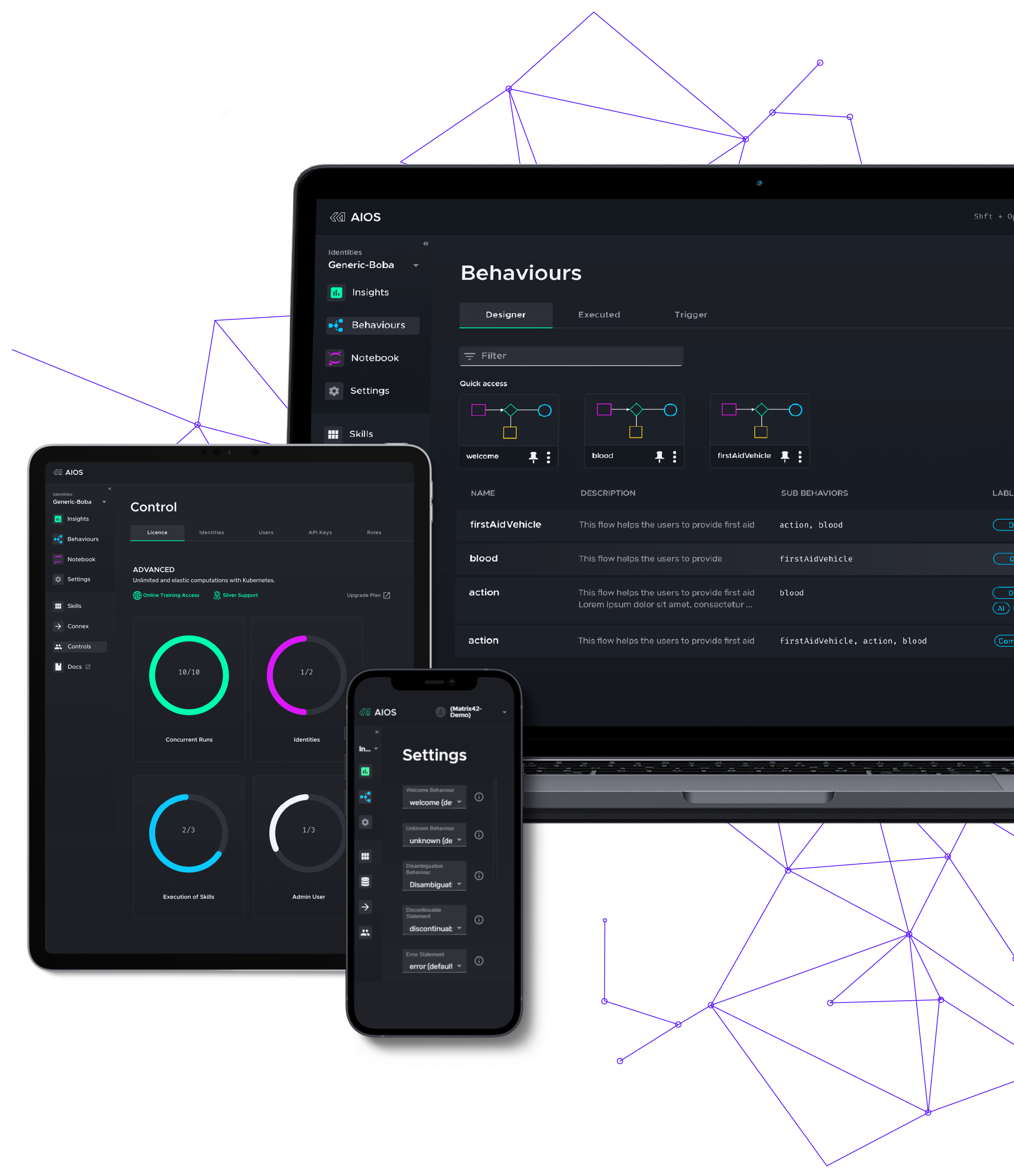

Our AI application adapts to your needs and integrates easily with your software infrastructure.

Business value is created only with the right software integration into your infrastructure. The AI-as-a-service concept makes the integration of artificial intelligence simply easy, which is done via defined and standardized APIs.

Our AI solution runs on AIOS, our AI platform. No matter which services you want to use and interconnect with other applications within your infrastructure, AIOS will make it possible.

We take care of a smooth integration into your infrastructure and are also available for you around the clock, thereafter.

Our three hosting variants:

- Public Cloud: As AI-as-a-Service provider we guarantee 99.9% availability –

dynamically scalable with shared resources as a cost-effective variant - Private Cloud: Data secure hosting in a private data center

- OnPremise: Integration into your internal infrastructure is possible as well

You decide, we deliver – with our AI platform, up and running in just 30 days!

Tomorrow’s technology available today

Our AI-based solutions are constantly learning and run without exception on our platform AIOS (AI Operating System). The platform is the stable basis through which a fast and smooth application is possible at all.

Through AIOS we guarantee:

- Fast availability of your AI Solution

- Smooth operation

- Constant monitoring

- Instant expansion and combination of multiple solutions

All our AI applications are guided by our ethical guidelines (Trustworthy AI) and meet the requirements for Responsible AI. Continuous development and enhancement of the applications are prerequisites.

Our support leads to a 100% success rate!

From the 360°Company AI Check to a Data Audit, or with the help of the AIOS Task Force create your prototype in 2 days:

We make it easier to get started and ultimately help you achieve an AI application that really suits you.

Our services include:

- Set-up & configuration

- Agile deployment of the software

- Application integration

- Continuous Machine Learning (ML)

Our supervised service will be at your disposal 24/7. We unburden your IT department and accompany you throughout your AI journey until you outpace the competition on your own.

Any questions about the AI Solution we just presented? Let's talk about it.

To respond to your request, we process the data you’ll provide in the form to the right. Thank you for taking the time to fill it in!

You can revoke your consent to this at any time. Please refer to the confirmation email and our privacy policy for more detailed information on data protection.

Artificial intelligence starter kit

Your companion with expert knowledge: We facilitate your entry into the AI world!

The three-step AI starter kit from Leftshift One enables your company to easily find its own AI solution. The 360° Company AI Check assesses your company’s AI potential and thus offers the perfect start. If you are already clear about this, a thorough data analysis (Private Data Audit) sets the course for the final step: Together with your team, our AIOS Task Force will develop a custom AI application in a 48h-Datathon.

Decide how you want to get started. But: Start your AI future now!